| Admin |

| Forum Overview |

Pages: (1) [1] » |

|

| CO2 Laser Cutting Machine for Wood, Acrylic |

| igoldencnc |

| |

|---|---|---|

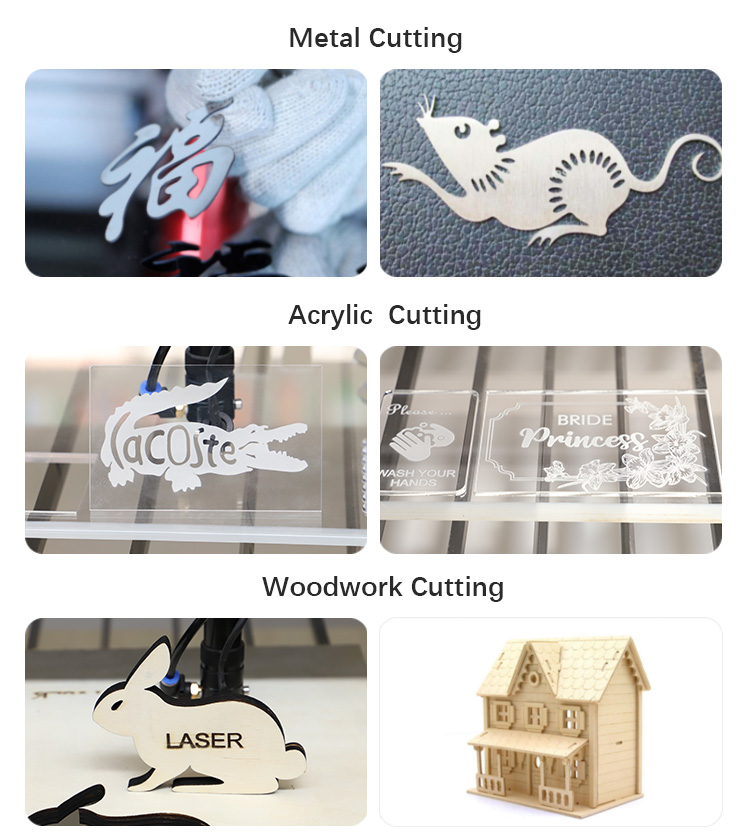

| Group: Administrator Level:  Posts: 33 Joined: 4/18/2023 IP-Address: saved  | Co2 laser engraving cutting machine is: 40w, 50w, 60w, 80w, 100w, 130w, 150w, 260w, etc,Cutting: Wood, Rubber, PVC, Polywood, Plexiglass, Paper, Organic Board, Mylar, MDF, Mat Board, Leather, Laminate, Fiberglass, Felt, Fabric, EVA Rubber, Cloth, Acrylic, ABS, etc.  The common processing materials of co2 engraving machine include acrylic, glass, wood, leather, cloth, plastic, two-color board, horn, cardboard, MDF, marble, and other non-metallic materials. And widely used in advertising processing, gift processing, packaging engraving, leather processing, fabric proofing, seal engraving, product marking, seal engraving and many other industries. Of course, to make exquisite acrylic products, you must have powerful processing equipment. What equipment is the first choice for acrylic processing? Look at the following analysis: Using traditional mechanical metal knife processing, the mechanical failure rate is high, the metal knife head is very easy to be damaged or blunt, and the cut is rough. If the mechanical pressure is too large, it will cause the acrylic plate to shrink and bend and deform, and the surface will be cracked. Moreover, the metal knife must be flame polished after cutting, which consumes high energy and has a long production cycle. Using Igolden laser cutting machine processing, the laser cutting head will not contact the surface of the board. Not affected by the shape of the workpiece, the laser processing is flexible and can process any graphics. This series of products uses high-precision linear guides in machinery. In linear reciprocating motion, it has a higher rated load than ordinary guides, and can withstand a certain torque at the same time. It can achieve high-precision linear motion under high load.  Perspex acrylic laser cutting machine produced by Igolden laser, the machine is equipped with imported linear guides. The cutting control system independently developed by our company has greatly improved the speed and accuracy of acrylic cutting, and is equipped with a self-developed high-performance laser tube. This series of machines has high configuration and stable performance. Features: C02 (single-head) laser cutting machine and engraving machine series Igolden’s relatively stable and mature products are currently very popular in domestic and foreign markets. This series of machines has fast cut speed, high precision, stable performance and high-cost performance. Optical design: The optical path system adopts a full set of imported laser lenses to ensure the long service life of the laser tube and high cutting efficiency. Industry applications: Engraving and cutting of paper, cloth, plastic, non-woven fabrics in the apparel and apparel industry and plush toy industry, non-metallic sheets such as acrylic sheets and medium-density decorative panels in the plastic industry such as handbags, gloves, models, advertisements, decorations, electrical appliances, and plastics Precision cutting. Products include laser cutting machine, laser marking machine, laser engraving machine, laser cutting laser marking, cutting machine, marking machine, fiber laser marking machine, CO2 laser marking machine, metal laser cutting machine, semiconductor laser marking machine , Laser equipment and more than 100 models, widely used in textiles, clothing, toys, industrial fabrics, advertising, leather, shoemaking, gifts, electronics, printing, packaging, automotive interiors, carpets, furniture, metal processing and other industries.

| |

| 10/13/2023 5:44:07 AM |    | |

|

| Thread-Info | |

|---|---|

| Access | Moderators |

| Reading: all Writing: all Group: general | none |

| Forum Overview |

.: Script-Time: 0.047 || SQL-Queries: 7 || Active-Users: 7,303 :.

Powered by ASP-FastBoard HE v0.8, hosted by cyberlord.at