Group: Administrator

Level:

Posts: 33

Joined: 4/18/2023

IP-Address: saved

|

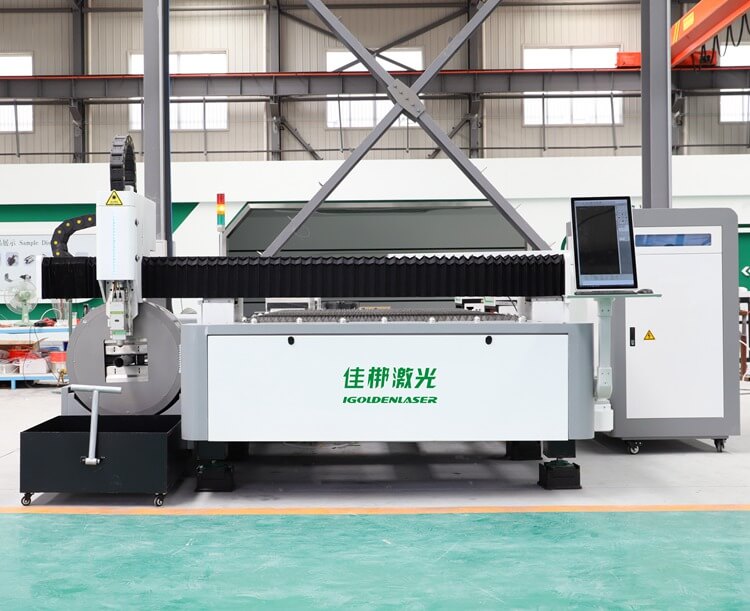

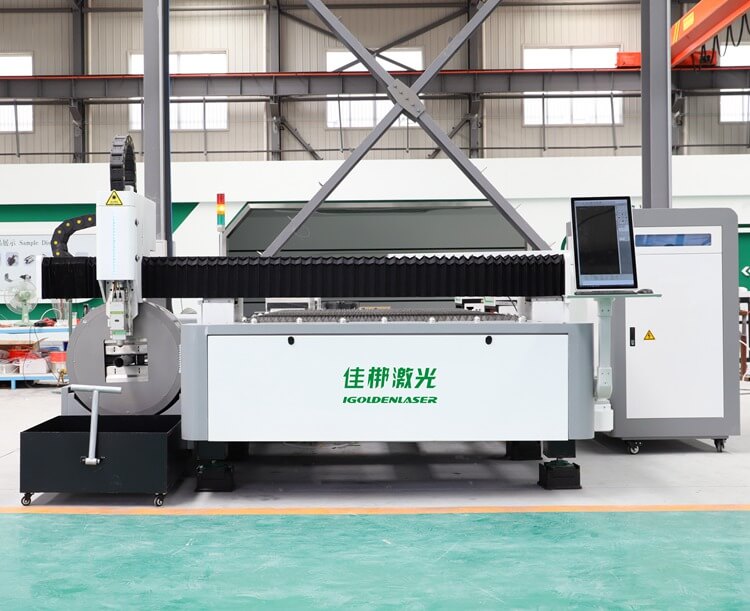

Plate and tube dual-purpose fiber laser cutting machine, can achieve two different profile cutting on the same machine tool, can cut metal sheet and pipe (square pipe, round pipe, channel steel, Angle steel, etc.). A multi-purpose machine, high cost performance, professional pipe cutting numerical control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

iGR-FH(+T) Series

Plate and Tube Laser Cutting MachineThe dual-use fiber laser cutting machine can realize the cutting of two different materials on the same equipment. It can cut both metal plates and tubes (including square tubes, round tubes, channel steel, angle steel, etc.). One machine with multiple functions, high cost performance, professional pipe cutting control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

The plate and tube integrated laser cutting machine can be said to be a multi-purpose machine, so that metal cutting machine manufacturers can cover most industries with just one machine. After buying a plate and tube integrated laser cutting machine, manufacturers no longer have to worry about changing the industry.

Advantages of laser cutting machine for plate and tube cutting:

1. High precision:

The traditional pipe cutting adopts manual methods, so each cut part is different, while laser processing uses the same fixture system, the processing design is completed by the programming software, and multiple processing steps are completed at one time, with high precision. In modern manufacturing, precision is of the utmost importance. Laser processing makes each part the same size;

2. Batch processing:

The standard pipe length is 6 meters. The traditional processing method requires very heavy clamping, and laser processing can easily complete the clamping and positioning of several meters long pipe, which makes batch processing possible;

3. Flexibility:

The laser can process various shapes flexibly, and designers can carry out complex designs, which is unimaginable under traditional processing methods;

Metal Sheet and Tube Laser Cutting Machine

Application of Fiber Laser Cutting Machine

Multi-industry applications: sheet metal industry, machinery industry, automotive industry, aerospace, cabinet industry, hardware industry, home appliance industry, doors and Windows industry, construction industry, mechanical and electrical industry, furniture industry.

Multi-material application: stainless steel, carbon steel, galvanized plate, electrolytic plate, aluminum, titanium, alloy, brass, copper, iron and other rare metal plate.

The CNC wood router on this page mainly refers to the 3 axis CNC router machine for CNC woodworking. The spindle of the CNC wood router carries the CNC router bits to move along the X, Y, and Z axes. As one type of the most commonly used wood CNC machine, it can cut, carve, engrave, mill, punch various types of wood boards. So it is also called CNC wood carving machine, CNC wood cutting machine, or CNC wood engraving machine.

Laser Rust Removal Machine

Laser cleaning has the characteristics of non-grinding and non-contact. It can not only be used to clean organic pollutants, but also inorganic substances, including metal rust, metal particles, dust, etc. The application effects include: rust removal, paint removal, and Oil stains, cultural relics restoration, de-gluing, de-coating, and de-plating.

|

|